Benefits

- Benefit 1: Keeping Water Clean

- Benefit 2: Strength & Long Term Reliability

- Benefit 3: Sealing Properties And Watertightness

- Benefit 4: Complete Drainage

- Benefit 5: Thermal Insulation Property

- Benefit 6: Environmentally Friendly

- Benefit 7: Re-locability

- Benefit 8: Flexible design and Modular shape

- Benefit 9: Simplicity of Handling and Site Installation

- Benefit 10: Cost Effective Maintenance Free Solution

General Specifications

Manufacturing Process :

Hot Pressed Sheet Moulding Compound (SMC) Compression Moulding

Up To 150 Degree Celsius

Tank Structural Support

- Tie-rod System

External : Hot Dipped Galvanised Steel

Internal : SS304 Tie-rod, Optional SS316* - Roof Support

PVC pipes with GRP roof panel stiffener

*Optional: ABS pipes - External Braced System

External : Hot Dipped Galvanised Steel

Internal : None (metal free inside)

Standard :

Singapore Standard SS245: 2014

Malaysia Standard MS 1390: 2010

similar to British Standard

BS 7491 Part 3:1994 and BS EN 13280:2001

Materials :

Sheet Moulding Compound (SMC) consists of:

- Resin

Isophthalic unsaturated polyester resin conforming to BS 3532 specification - Fibre Glass

Alkali free fibre glass – Type E glass

Sealant :

- Nontoxic PVC foam

- EPDM Rubber

Bolts, Nuts and Washers :

- External

Standard: Hot Dipped Galvanised Steel

*Optional: SS 304/316 - Internal

Standard : SS 304 (In-contact with water)

*Optional: SS 316 (In-contact with water) - Roof

Standard: Hot Dipped Galvanised steel

* Optional: SS 304/316

Water Level Indicator :

- Standard: Reversed Reading

Mechanical Ball Float Type (Cat & Mouse) - *Optional: Direct Reading Clear Tube Type

Ladder :

- External

Standard: Hot Dipped Galvanised Steel, 300mm width - Internal

Standard: PVC or Aluminium, 300mm width

*Optional: GRP or SS 304/316, 300mm width

Nozzle Panel :

- Pipe nozzles flange not inclusive

- Flat panels will be provided upon request

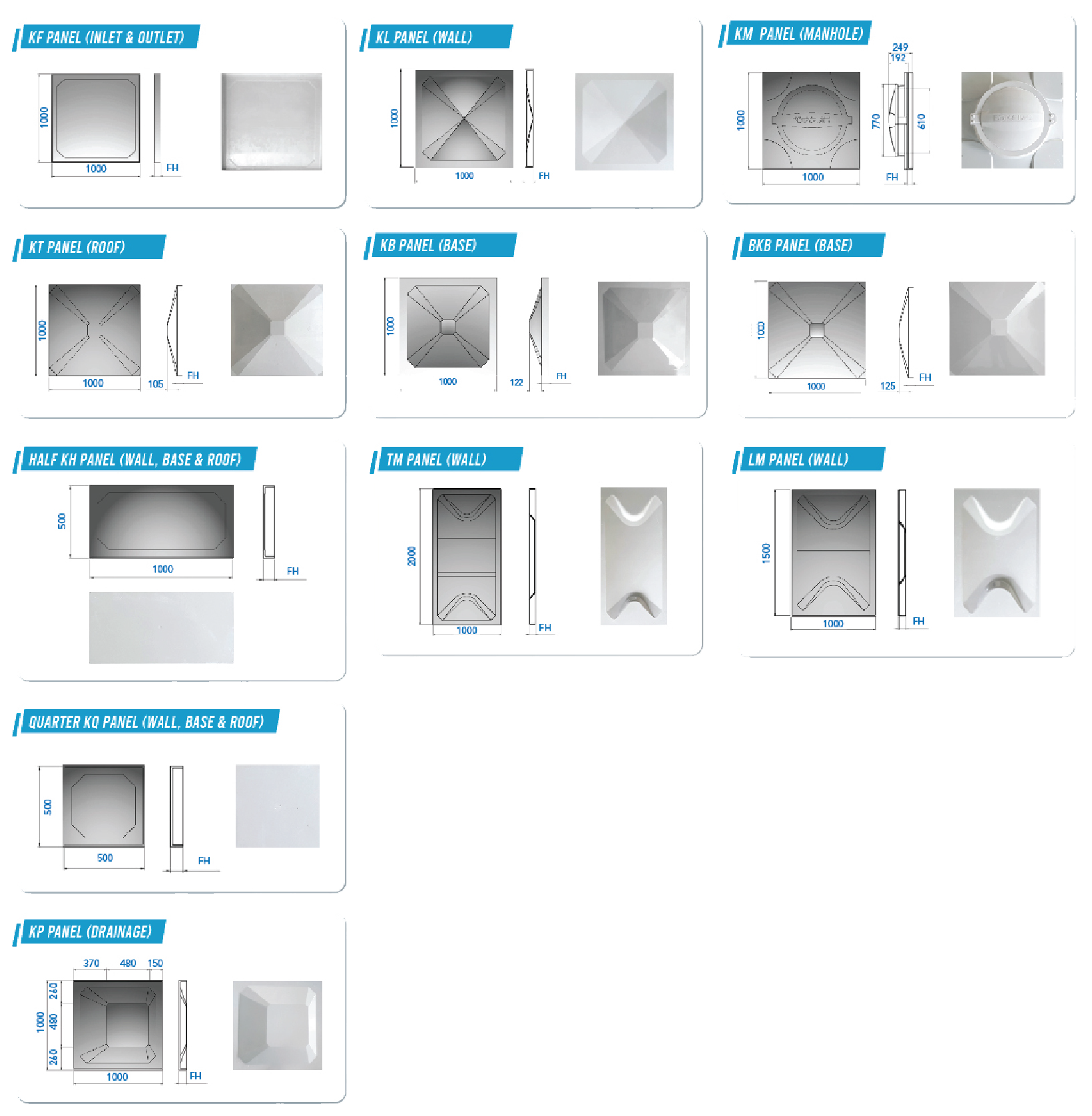

GRP Panel Design

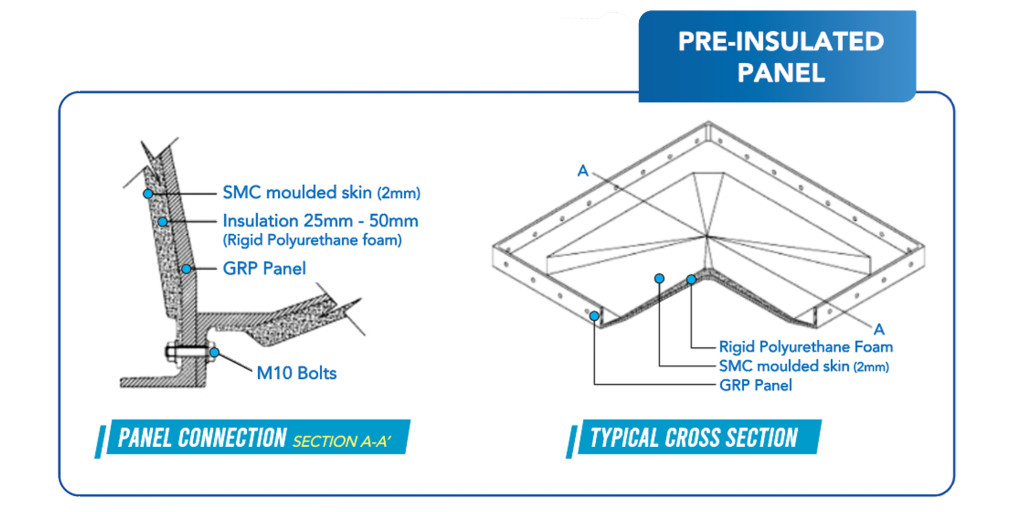

PRE-Insulated Panel

By encapsulating a 25mm ~ 50mm layer of rigid polyurethane foam, POTAGLAS pre-insulated panel could maintain the desired water temperature stored inside the tank under extreme temperature condition. POTAGLAS pre-insulated panel could be selected for water storage where there is a need to stabilize the temperature against extreme heat or freezing conditions so to prevent dew formation.

*Flange height (FH) varies according panel series

*Standard colour: gray

Performance of Panel

| CHARACTERISTICS | POTAGLAS GRP TANK PANEL PERFORMANCE | ACCEPTANCE CRITERIA (SS 245:2014 SPECIFICATION) |

|---|---|---|

| Tensile Strength (MN/m²) | > 103 | >70 (min) |

| Bending Strength (MN/m²) | > 171 | > 100 (min) |

| Elastic Modulus in Bend (MN/m²) | > 12260 | > 6000 (min) |

| Glass Content (%) | > 40 | > 25 (min) |

| Barcol Hardness | 57 | >30 (min) |

| Water Absorption (%) | 0.1 | 0.5 (max) |

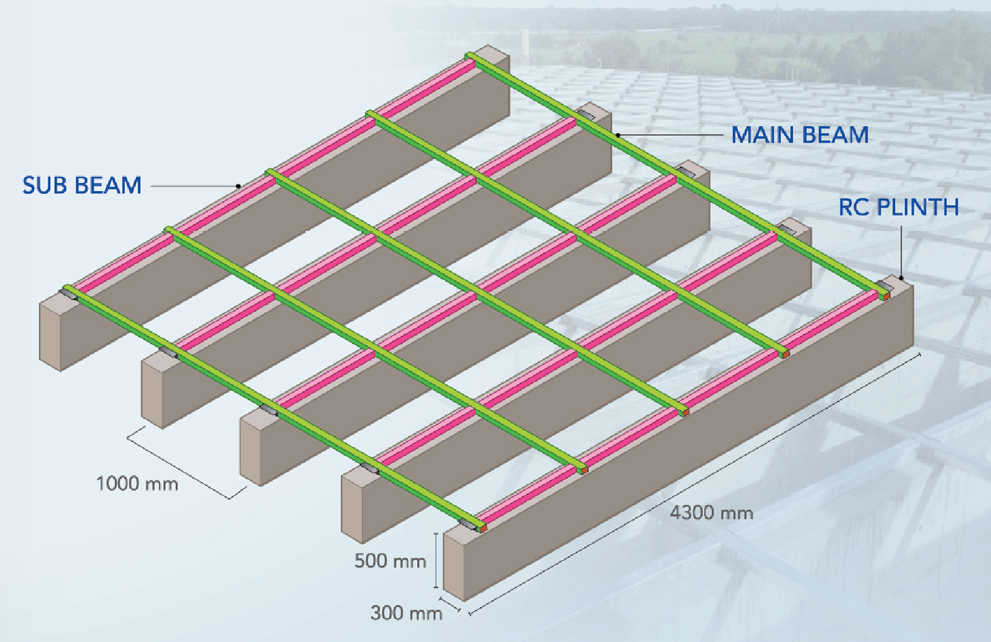

Skid Base Specifications

| TANK HEIGHT | MAIN BEAM | SUB BEAM | CONCRETE PLINTH DISTANCE |

|---|---|---|---|

| 1.0m | HDG Hollow Section 50mm x 50mm x 3mm | HDG Hollow Section 50mm x 50mm x 3mm | 1000mm c/c *c/c = centre to centre |

| 1.5m | HDG Hollow Section 50mm x 50mm x 3mm | HDG Hollow Section 50mm x 50mm x 3mm | 1000mm c/c *c/c = centre to centre |

| 2.0m | HDG Hollow Section 50mm x 50mm x 3mm | HDG Hollow Section 50mm x 50mm x 3mm | 1000mm c/c *c/c = centre to centre |

| 2.5m | HDG Hollow Section 50mm x 50mm x 3mm | HDG Hollow Section 50mm x 50mm x 3mm | 1000mm c/c *c/c = centre to centre |

| 3.0m | HDG Hollow Section 50mm x 50mm x 3mm | HDG Hollow Section 50mm x 50mm x 3mm | 1000mm c/c *c/c = centre to centre |

| 3.5m | Hollow Section 50mm x 50mm x 4.5mm | Hollow Section 50mm x 50mm x 4.5mm | 1000mm c/c *c/c = centre to centre |

| 4.0m | Hollow Section 50mm x 50mm x 4.5mm | Hollow Section 50mm x 50mm x 4.5mm | 1000mm c/c *c/c = centre to centre |

*Potaglas reserves the right to provide alternate skid base designs depending on the site condition and material availability.

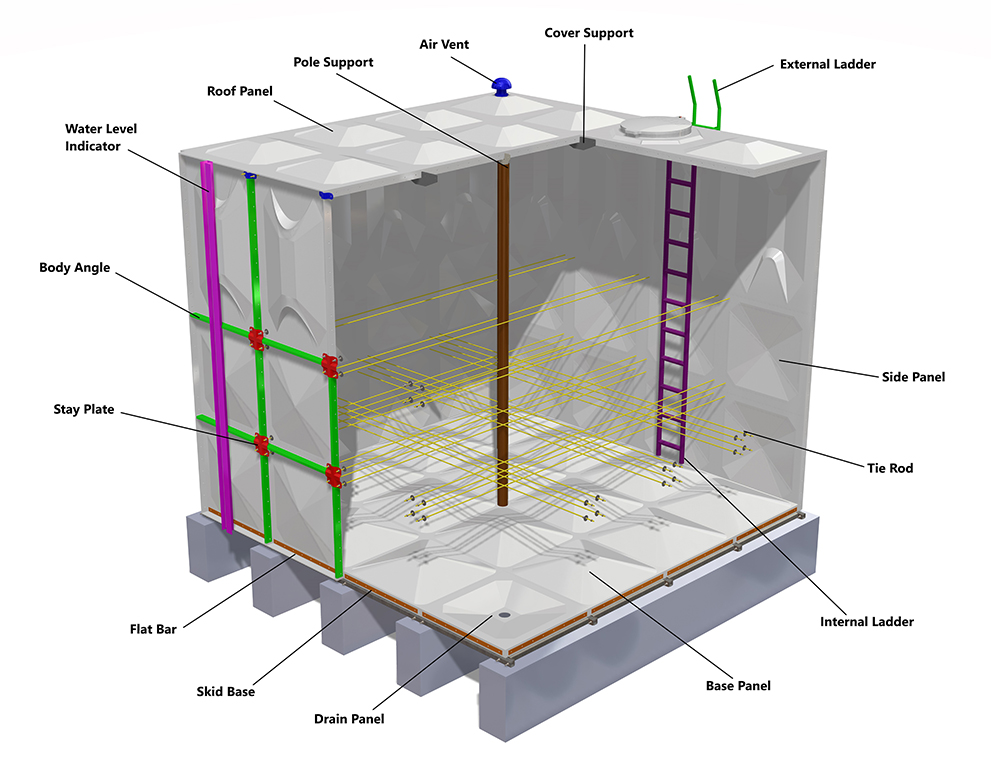

Internal Tie-Rod Design

| MAIN COMPONENTS | EXTERNAL STRUCTURAL SUPPORT | INTERNAL STRUCTURAL SUPPORT | TANK ACCESSORIES |

|---|---|---|---|

| Top Panel | Body Angle | Pole | Access Manhole |

| Side Panel | Corner Angle | Pole Support | Air Vent |

| Bottom Panel | – | Tie Rod | Water Level Indicator |

| Drain/Pit Panel | Flat Bar | Roof Support | Internal Ladder |

| Stay Plate | In Corner Bracket | External Ladder |

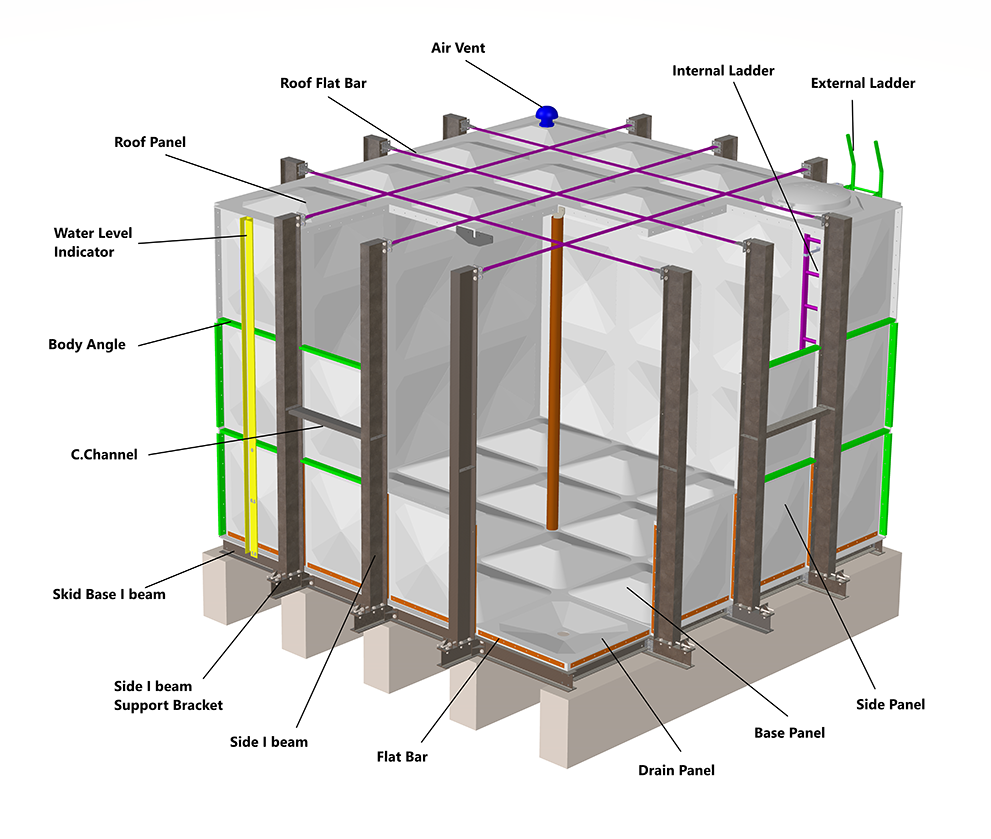

External Braced Design

| MAIN COMPONENTS | EXTERNAL STRUCTURAL SUPPORT | INTERNAL STRUCTURAL SUPPORT | TANK ACCESSORIES |

|---|---|---|---|

| Top Panel | Flat Bar | Pole | Access Manhole |

| Side Panel | Body Angle | Pole Support | Internal Ladder |

| Bottom Panel | – | Roof Support | External Ladder |

| Drain/Pit Panel | C-Channel | In Corner Bracket | Air Vent |

| Vertical I Beam | Tube Level Indicator | ||

| Roof Flat Bar | |||

| Side I Beam Support Bracket | |||

| External Bracing Support |